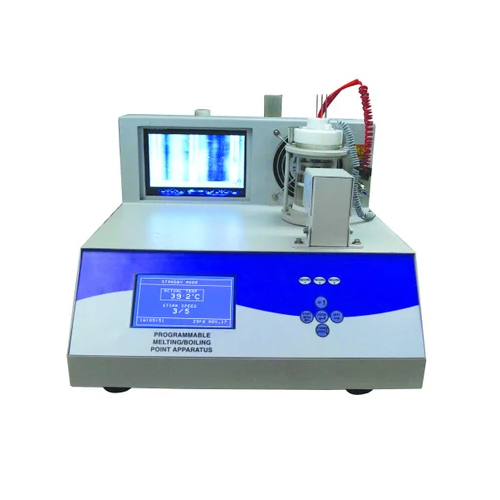

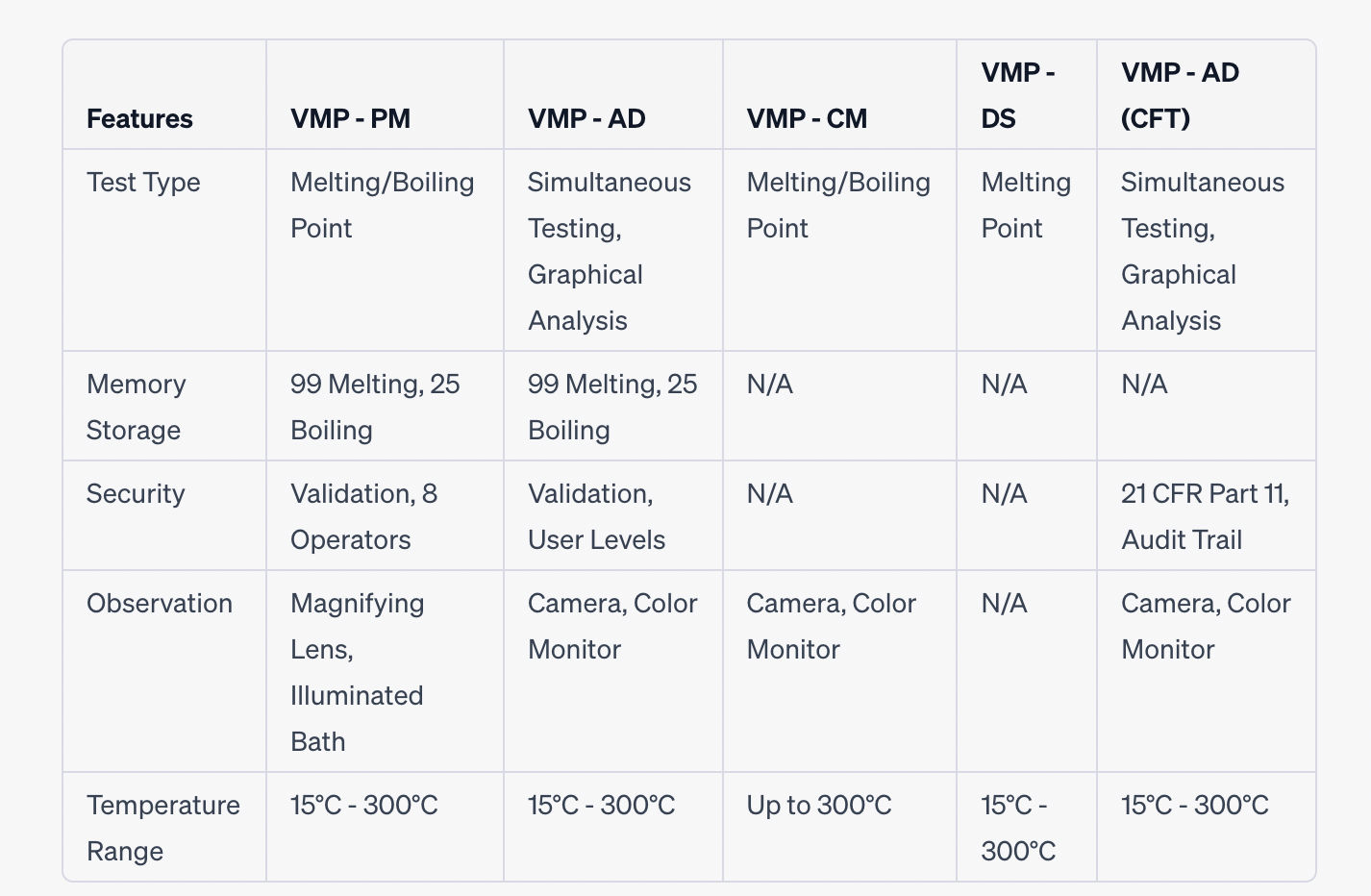

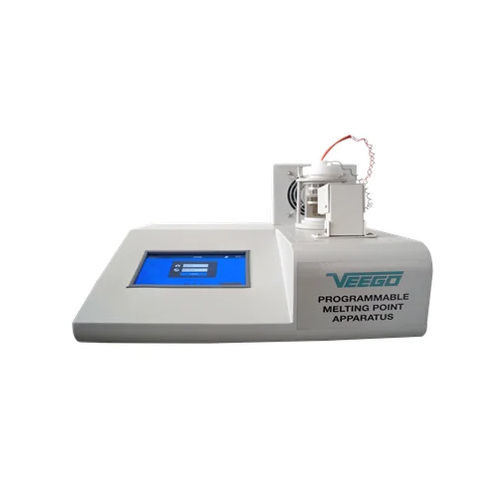

कैमरा VMP CM के साथ मेल्टिंग और बोइलिंग पॉइंट उपकरण

1 आईएनआर/टुकड़ा

उत्पाद विवरण:

- माउंटिंग टाइप Bench-top

- तापमान Ambient to 400°C

- ऑपरेटिंग वोल्टेज 230 V AC

- उपयोग प्रयोगशाला

- मापने की सीमा 0 to 400°C

- नमी up to 80% RH

- ऑटोमेशन ग्रेड Semi-automatic

- अधिक देखने के लिए क्लिक करें

X

कैमरा VMP CM के साथ मेल्टिंग और बोइलिंग पॉइंट उपकरण मूल्य और मात्रा

- टुकड़ा/टुकड़े

- 1

कैमरा VMP CM के साथ मेल्टिंग और बोइलिंग पॉइंट उपकरण उत्पाद की विशेषताएं

- नीला और भूरा

- USB for camera, Digital controls

- Manual observation, camera assisted

- 230 V AC, 50 Hz

- Melting point: Ambient to 400°C, Boiling point: up to 400°C

- पिघलने और क्वथनांक उपकरण

- Standard glass capillaries

- Digital, Microprocessor based

- ±0.5°C

- Fitted with high-resolution camera, LED illumination, auto stirrer, digital display

- 50 Hz

- एमएस

- 3 Capillaries at a time

- औद्योगिक

- 230 V AC

- प्रयोगशाला

- Ambient to 400°C

- 6.5 kg

- Bench-top

- 0.1°C

- Instantaneous (with real-time video recording)

- 0 to 400°C

- up to 80% RH

- Digital LCD display

- Simultaneous melting/boiling point determination

- Semi-automatic

कैमरा VMP CM के साथ मेल्टिंग और बोइलिंग पॉइंट उपकरण व्यापार सूचना

- 3 दिन

उत्पाद वर्णन

उन्नत डिजिटल पिघलने और क्वथनांक उपकरण, जो पिघलने या क्वथनांक का निरीक्षण करने के लिए ग्राफिक डिस्प्ले, कलर मॉनिटर और कैमरे से सुसज्जित है।

Tell us about your requirement

Price: Â

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

मोबाइल number

Email

जांच भेजें

जांच भेजें एसएमएस भेजें

एसएमएस भेजें मुझे निःशुल्क कॉल करें

मुझे निःशुल्क कॉल करें